A couple of weeks ago, on 9 October 2020, I took part in a seminar for the Tony Blair Institute for Global Change, called “UK Industrial Strategy’s three horsemen: COVID, Brexit and trade wars”. This featured as speakers me, the economist Dame Kate Barker, and Anand Menon (Director of “UK in a changing Europe” at Kings College London), and was chaired by Ian Mulheirn. There is a YouTube video of the event here. Here is a slightly tidied up version of what I said.

It’s a real pleasure to be speaking at this event – and especially to be sharing a virtual platform with Kate Barker, from whom I learnt so much as a colleague working on the Industrial Strategy Commission back in 2017. Our final report then was intended to inform the discussion around the 2017 White Paper on industrial strategy. Now industrial strategy is back on the agenda – we read that the the government is planning to “rip up” the 2017 strategy, producing a new document with a heavy focus on science and technology.

Despite everything that’s happened since 2017, I agree with Kate that the principles we laid down do stand the test of changing times. Since then, the focus of my own work has been on the link between R&D, innovation and productivity, and the way regional imbalances in economic performance reflect regional imbalances in state spending in R&D.

But how is this all changed by the three horseman of the apocalypse – COVID, Brexit and trade wars – that we’re asked to discuss?

Brexit

We can talk about the link between Brexit and industrial strategy both in terms of cause and effect. Failures of industrial strategy contributed to the political conditions that led to Brexit, and the changes that Brexit will force on the UK’s economy will demand a different industrial strategy for the new economic model that the country will have to adopt.

Much written on the connection between “left behind communities” and the Brexit vote, and the relationship is possibly more complicated than simple accounts might suggest. But, as the economic geographer Philip McCann has demonstrated in his analysis of “geographies of discontent” , the UK is an outlier amongst developed countries in the scale of its economic imbalances. The greater Southeast looks like a prosperous Northern European country. The rest of the country looks like East Germany, Southern Italy or Portugal. In fact, East Germany has recovered from 40 years of communism faster than the North of England has recovered from the deindustrialisation of the 1980’s.

These regional imbalances are reflected in living standards and other measures of prosperity, including life expectancy and health outcomes. But at the root of the issue is a huge imbalance in productivity. In fact, the imbalances show up more strongly in productivity than in living standards, because the UK runs an effective transfer union – money is moved up from the greater Southeast – the only parts of the country to make a surplus on the government current account – to the rest of the country.

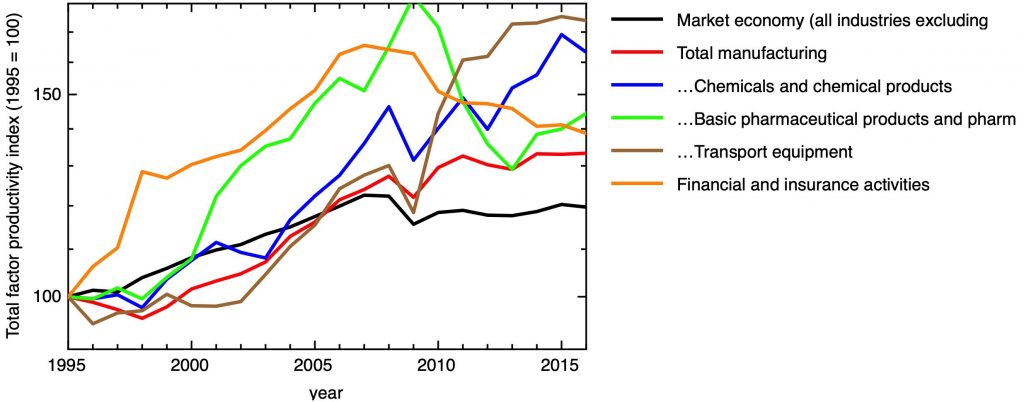

But the paradox is that while we transfer money to cover current spending, we concentrate the investments that build productivity growth in the already prosperous greater southeast. My own focus has been on Research and Development: here nearly half the public spending on R&D is concentrated in London and the two two subregions containing Oxford and Cambridge. R&D isn’t the only thing that matters in driving productivity growth, but it is associated with high value companies operating at the technological frontier and innovative start-ups, which anchor strong regional innovation ecosystems and produce highly prosperous knowledge intensive economies like those around Cambridge and Oxford.

Even more paradoxical is the fact that public spending on R&D is even more geographically concentrated than private sector spending. This means that potential spillovers from private sector R&D spending are being left uncaptured. We have regions like the North West, with highly productive, R&D intensive industries such as chemicals and pharmaceuticals, and the East Midlands, with its strong private sector innovation in automotive and aerospace, where the innovation potential of the regional economies isn’t being exploited to the full because the public money doesn’t follow the private.

On the other hand, there are some places that don’t have enough R&D of any kind, public or private. In Wales and the Northeast, for example, low investment in R&D leads to weak innovation economies, with poor productivity performance and low demand for skills

It is failures of industrial strategy that have led to a divided country, and those divisions have brought us sour politics.

Trade Wars

Moving onto the effects of Brexit – and the wider sense of a retreat from globalisation – we’re likely to find that the economic model that the UK has chosen is likely to be particularly threatened. Some of our highest productivity and most export oriented sectors have succeeded by becoming highly integrated in transnational value chains, and it is these sectors that are most at risk from the trade dislocations that Brexit threatens.

The UK’s automobile industry is a prime example. This has made a remarkable comeback from a low-point in the mid-2000’s – perhaps an unsung success of a modern industrial strategy which began with Mandelson’s time in the Business department at the end of the new Labour period, and persisted into the Coalition, with considerable policy continuity. But a finished car that rolls off a production line in Sunderland or Solihull combines components and parts that have been shuffled back and forth from a network of suppliers all across the world. This leads to efficient car production, but it’s going to be very difficult to adapt to a post-Brexit world where there are likely to detailed rules on local origin for the export of vehicles to the EU.

Brexit isn’t the only event that’s likely to give us hard lessons about technological self-sufficiency. We can see the effects of a much colder attitude to China in the USA in the pressure on the UK to lessen the involvement of Huawei in the 5G network, and the exclusion of the UK from the EU’s Galileo project for a satellite positioning has resulted in a scramble for a UK alternative. I suspect that politicians and policy makers severely underestimate the degree to which the UK has lost technological self-sufficiency in a whole range of sectors. I also wonder whether a wider sense of loss of what one might call technological sovereignty has itself contributed to the anxiety that culminated in Brexit.

I believe that the UK will need to rebuild some of its technological capacity if it is to remain a prosperous country, and that this will need to be a central ingredient of a more activist industrial policy. But that leaves some big questions. How much, in what sectors? The UK is a relatively small country in a big world economy. We will need to think very deeply about our place in the evolving trading systems of a world that might look very different to the post-cold-war, globalising world that policy makers have grown up in. An industrial strategy does need to be founded on a clear view about what kind of economy the UK wants – and can realistically hope – to become.

COVID-19

We’ve known for some time that increasing globalisation puts the world at greater risk of a pandemic, and with COVID-19 those fears have been realised. The closer entanglement of natural ecosystems with human society leads to more pathogens crossing from the animal world into people; then the worldwide traffic of business people and tourists spread the disease across the world before health systems have a chance to respond, as we have seen with such tragic consequences over the last year.

It’s too soon to unpick all the effects COVID-19 will have on the economy, and the implications that those effects have for the UK’s industrial strategy, but we can already start to see some themes emerging. Different sectors have been affected in different ways, with an obvious severe (but hopefully time-limited) blow to hospitality and tourism, and perhaps more far-reaching effects on commercial real estate as some pandemic induced changes in working practises are permanently adopted.

One very important question for the UK concerns the shape of the future civil aerospace industry. It’s difficult to know how future patterns of international mobility will change, but any permanent reduction will have a serious impact on one of the UK’s highest productivity industries. As a specific example, Rolls-Royce is one of the UK’s few world class innovative engineering companies of any size, but its dependence on long-haul air traffic makes the company – and the cities like Derby that depend on it – very vulnerable.

Rolls-Royce has been bailed out by the government once before, following its bankruptcy in 1971. I believe that letting Rolls-Royce fail now should be unthinkable, because of the dissipation of concentrations of high level skilled people, and the loss of innovation capacity in areas like the East Midlands that would follow. But what form should any bail-out take – and how should it take into account bigger imperatives such as the net zero greenhouse gas target?

What can we learn about our industrial strengths and weaknesses from the experience of our response to the pandemic? We went into the pandemic thinking we had the advantage of a world-class life sciences sector, but after the event we can’t say the UK has excelled in its response.

It’s certainly true that parts of our life sciences sector are excellent, and if the Oxford group or the Imperial group produce an effective vaccine against covid-19, and if the pharmaceutical industry is successful in rapidly scaling up its manufacture, that will be a huge achievement and an invaluable contribution to world health.

But in other important areas – in public health, diagnostics, the care sector – the UK’s weaknesses have been savagely exposed. We have learnt about weaknesses in supply chains for basic supplies like PPE and generic pharmaceuticals.

I think we made a category error in thinking that the “life sciences sector” is a sector at all. We have a strong pharmaceutical sector which historically been enormously productive (though not without recent difficulties), exploiting the UK’s excellent biomedical science base to produce drugs for the most lucrative world markets (particularly those of the USA). But we have done much worse in driving and implementing the kinds of innovation that serve the health needs of the UK’s own population.

The fourth horseman

There is, of course, a fourth horseman of the industrial strategy apocalypse, that is more important than any of the three we have been asked to discuss. That is climate change and the huge economic transition that the need to decarbonise our energy economy requires. It is an entirely positive development that the government has committed to a target of net zero greenhouse gas emissions by 2050, and that there is a wide political consensus in support of this target, or indeed a more ambitious goal. But I’m not convinced that policy makers and the public fully understand the magnitude of the task.

We need not just to decarbonise the electricity sector as it stands now; as we electrify other forms of energy use, we will need to at least double generating capacity. We need to decarbonise transport and domestic heating, probably using hydrogen as an energy store and vector, especially for hard to decarbonise industries like steel. We will need as much offshore wind as we can get (probably including new technologies like floating wind), we will need new nuclear build, possibly including new high temperature designs to make hydrogen from process heat.

This energy transition will be a huge dislocation. We have to do it, but we shouldn’t expect it to be without cost. People rightly talk about the new “green” jobs this transition will produce – but that’s not an unmixed blessing. If the new energy systems need to employ more people than our current fossil fuel based system, that implies a drop in productivity. We will have to apply more resources to achieve the same energy benefits, and those resources won’t be available to satisfy other wants and needs. Innovation, to create new zero carbon technologies and improve existing ones, will be urgently needed to drive down those costs, and that innovation – carried out in parallel with the deployment of existing technologies – should be a priority of industrial strategy.

The energy transition does have potential benefits for regional economic inequality, though. Much of the innovation and deployment of low carbon technologies should happen outside the prosperous Southeast – for example in Teeside and the Humber, in Cumbria and the Wirral. This should be an important part of the “levelling up” agenda.

An industrial strategy for our times

To sum up, the ravages of these four horseman mean that our economy will need to be transformed. That transformation needs to be driven by innovation, and it needs to be informed by a clear view of the enduring challenges the UK faces and a realistic assessment of the UK’s place in the world. As Kate stressed, the challenges are obvious: climate change, weak wage growth, the cost and effectiveness of health and social care, failing places. The need for a new start does give us a chance to spread the benefits of innovation more widely across the country, and we should seize that opportunity.